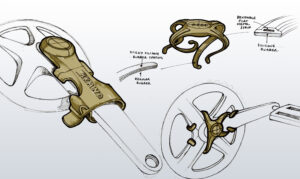

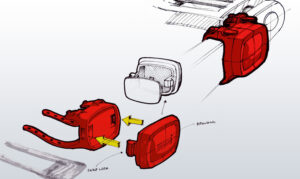

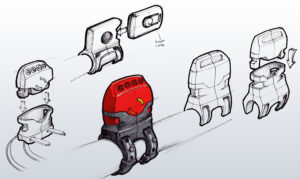

One of my early projects in 2016 required designing bike sensors and trackers of varying functions and features. One thing they all had in common was they were meant to be used outdoor in motion, thus they had to have some level of dust and moisture protection. I started the process with studying the components of the device and understanding what my client needs for my output. The client provided the user requirements and some features of the device, and they were clear about what they wanted for the enclosure and sensor design.

![]()

![]()

![]()

I created several design studies for the device enclosure, including options for clamping the device onto the bike handles. The client had been quite specific on the placements of both the tracker and the sensor. Some of the designs I made featured flexibility for the purpose of adaptability to varying bike part designs.

After further modifications have been made to the chosen tracker design, the client asked for 3D models of the device enclosure and the clamp. I built the models specifically for 3D printing so the client can print an test the enclosure and the clamping, before finalizing the model for turnover.