I have worked on ambitious startup projects trying to develop tech products, with multiple functions and features. The novelty of new technology, in particular, can build up excitement and curiosity that can be leveraged to drive the design process. On the other hand, new tech functionality and features can also have requirements that are difficult and tricky to accommodate in design, especially in the case of new inventions and startup projects.

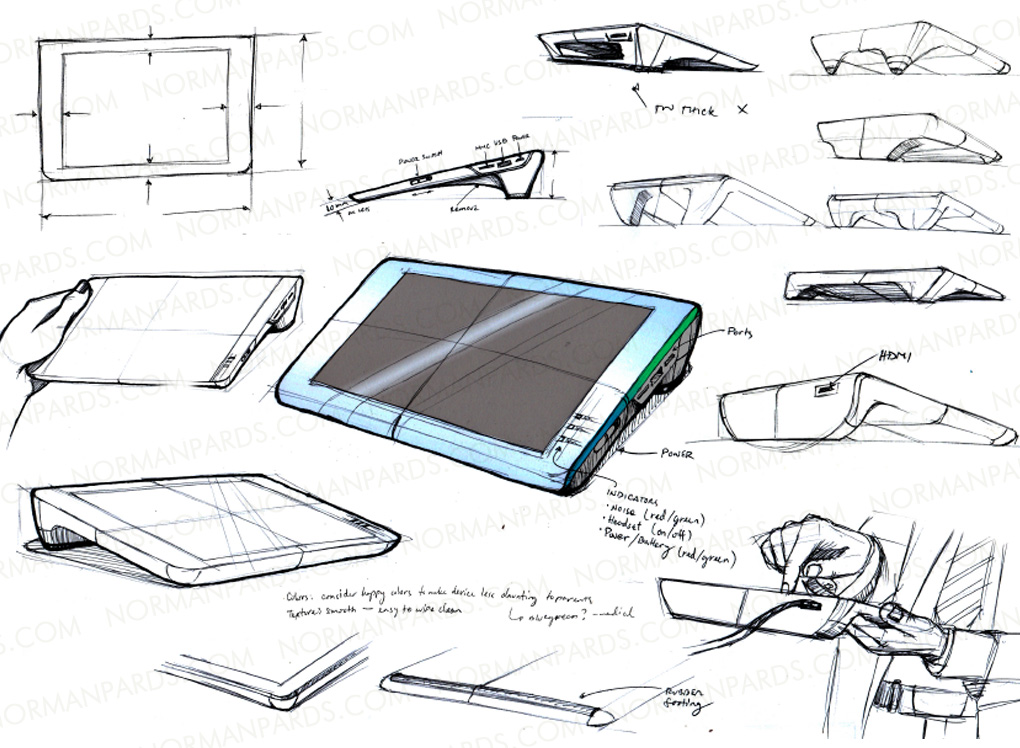

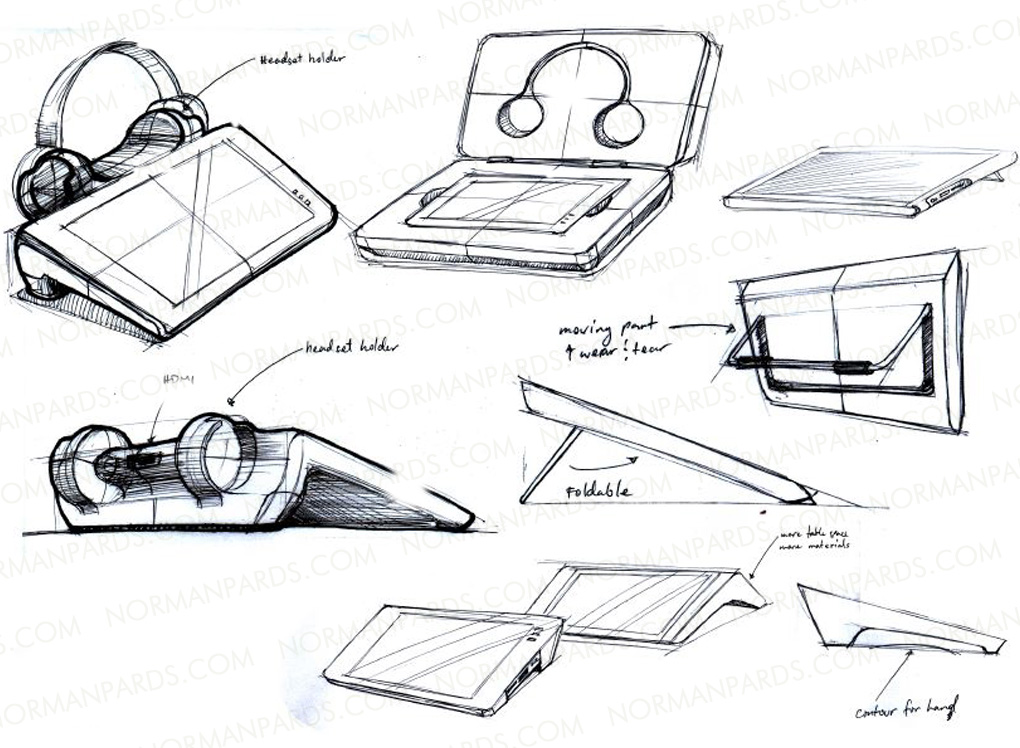

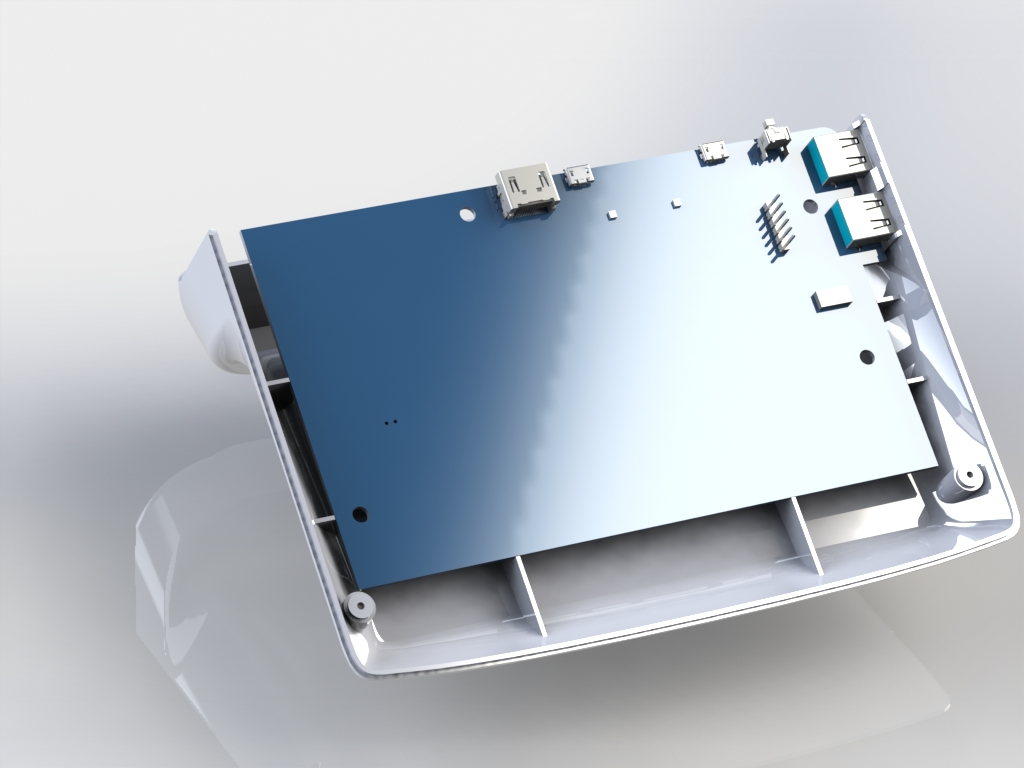

Device enclosures are often interesting and pleasantly challenging to work on. Finding the proper balance between aesthetics and functionality can either be an exciting or frustrating challenge. I worked on a medical device in 2018, aimed at developing a hearing screening device for infants that had complex capabilities and functionalities. One of the requirements is to design a handheld screen that doctors can either hold or set on a table during patient testing. The device needed to work well with specialized audio equipment and sensors. Since the project was funded by a government program, there were strict limitations on funding and purchase transactions, which limited the development team’s capability to use modern components that are advanced and more compact. As a solution, I designed the device enclosure to be as compact as possible, while housing in a number of components critical to the technology’s function and purpose. I had to remain objective to the goal, and constantly worked closely with the engineers involved in the project. (Tech Article: https://region8.healthresearch.ph/index.php/8-news/171-ph-us-researchers-develop-early-detection-device-for-filipino-infants-to-prevent-hearing-loss)

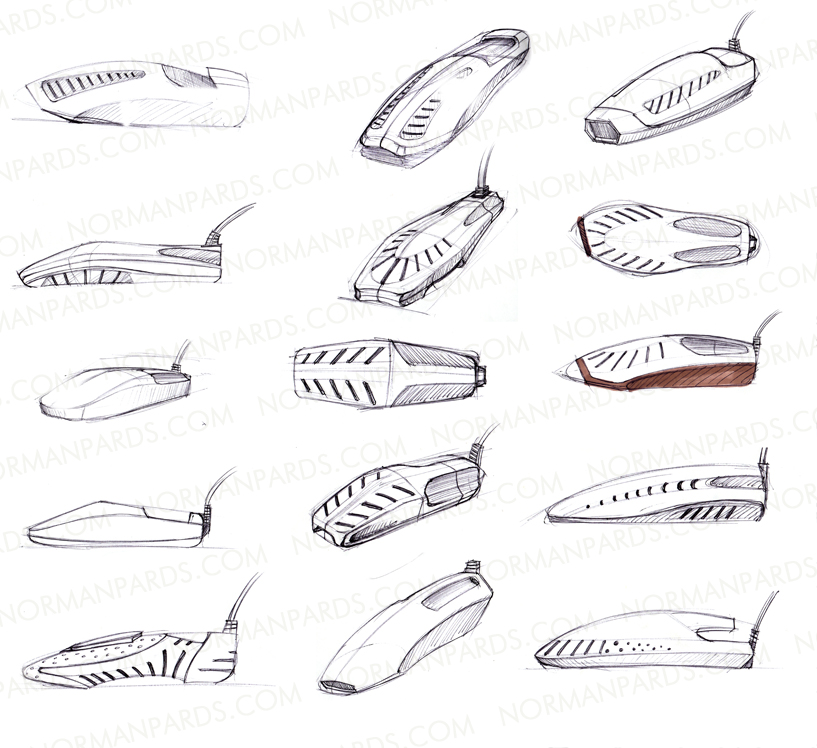

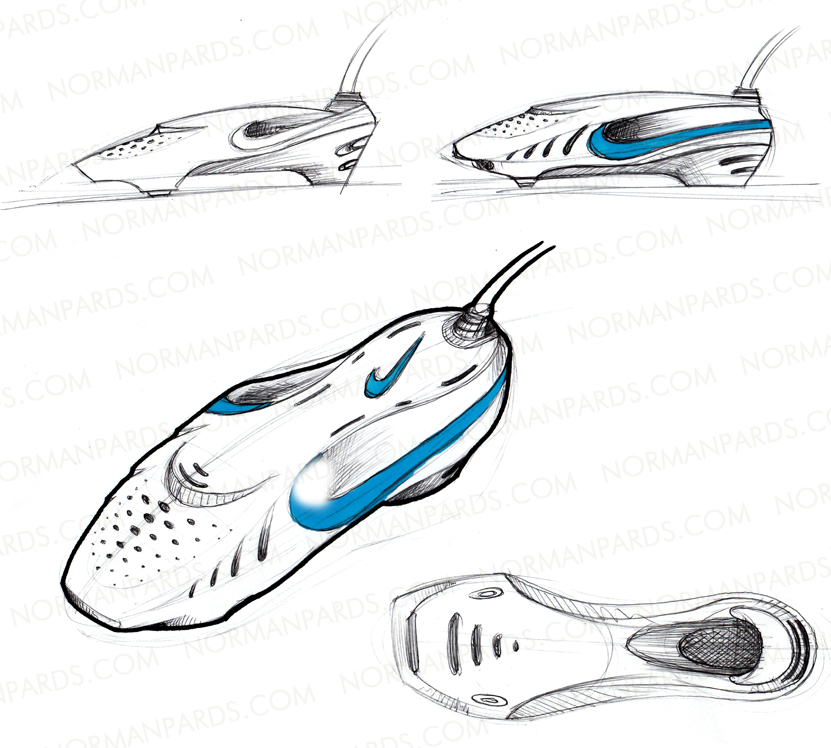

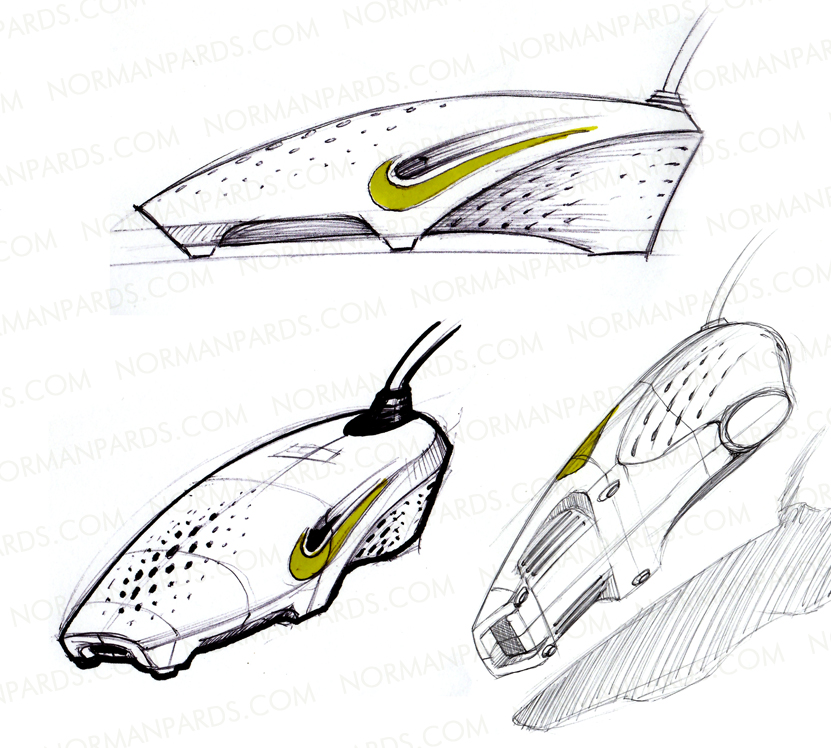

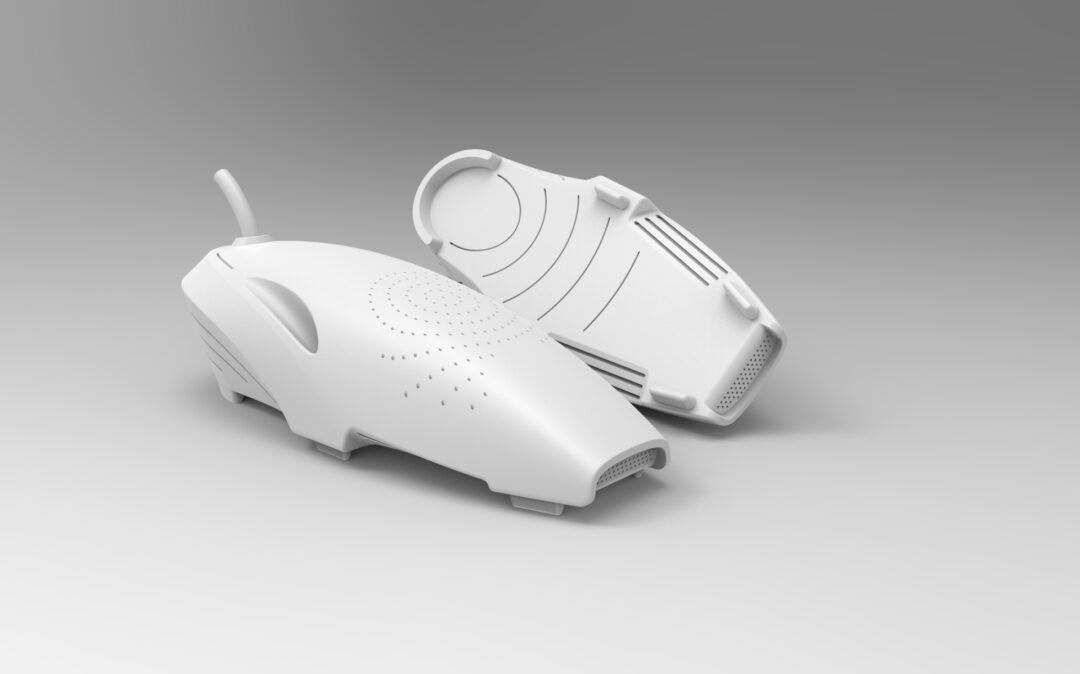

Back in 2016, I also had the pleasure of designing a device that’s fairly simple, though I wasn’t actually aware already existed — a shoe dryer. I live in the Philippines, a tropical country , so we didn’t need any technology to dry our shoes for a few hours. Requirements for the project were straightforward — provide ideation sketches and model the chosen design in 3D.

The main challenge in this project was understanding airflow and making sure that every part of the shoe gets exposed to the warm air emitted by the device. Thus, I identified key areas for positioning of the vent holes while exploring different forms. The client chose to merge several designs together, and I obliged to create several, more detailed illustrations of a few design options. Eventually, I was asked to create a more generic 3D model of the chosen design.

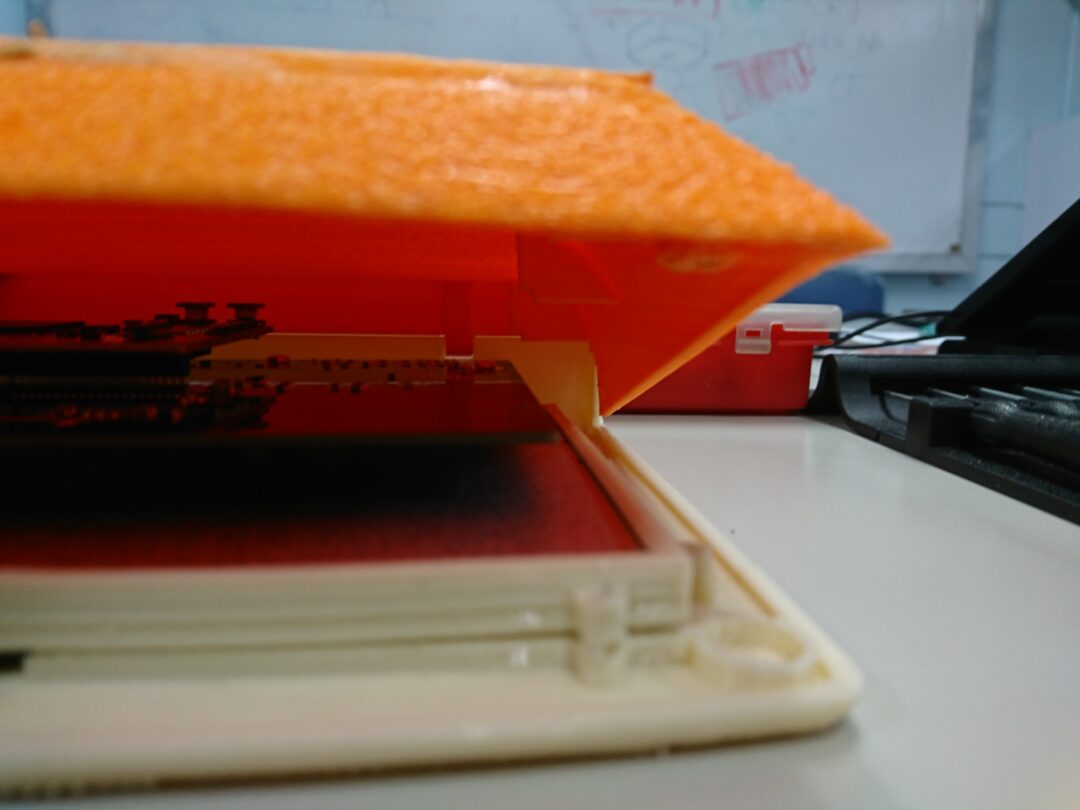

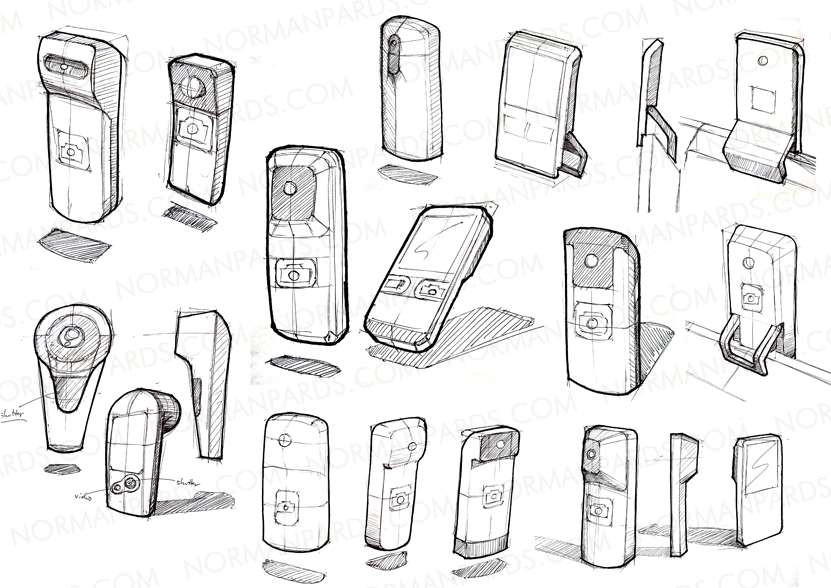

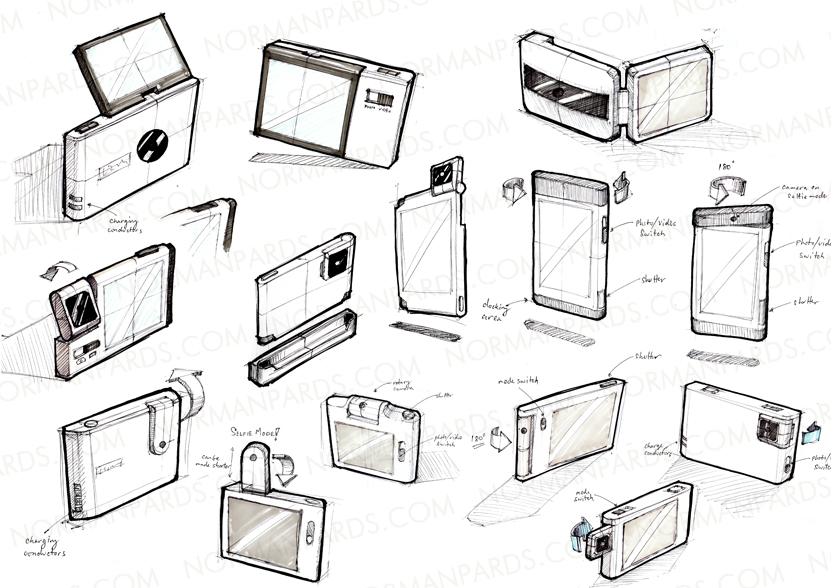

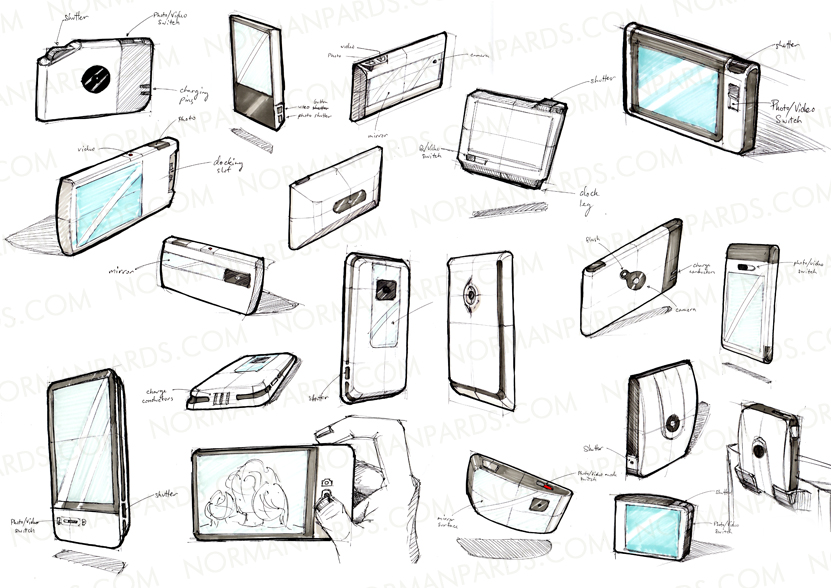

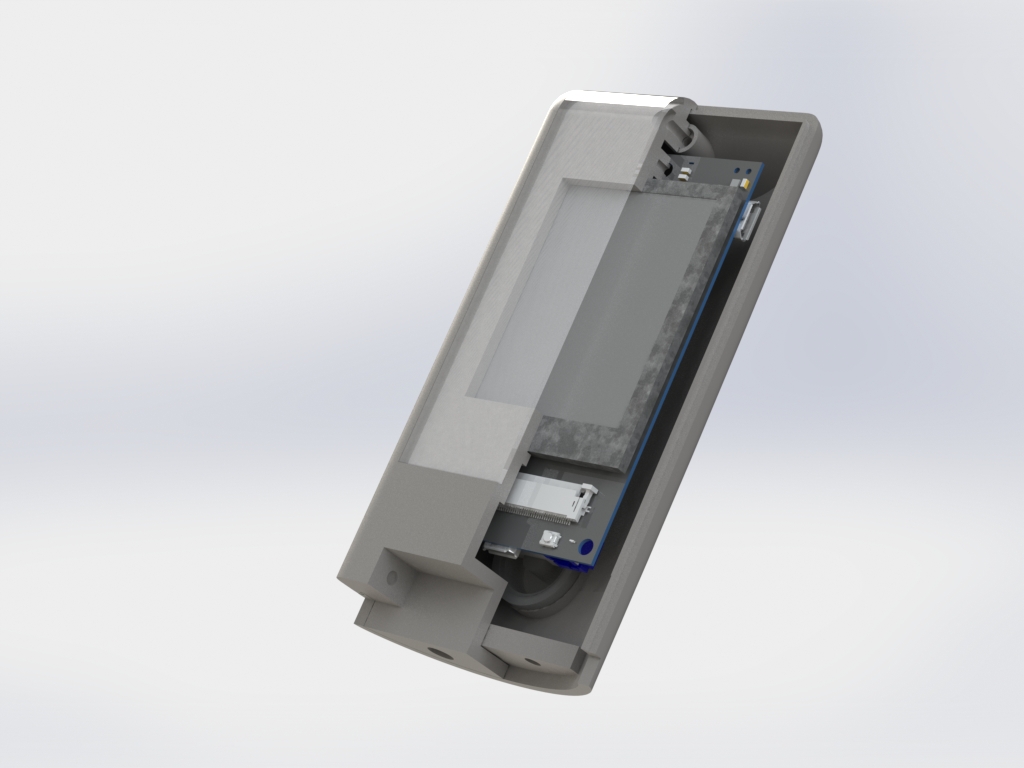

In 2017, a client asked me to produce concept sketches for a camera with a specific function and purpose. It was my first time to design a camera, however very little information was given as to the functionality and purpose of the device, for confidentiality reasons I pressure. Nevertheless, it presented an opportunity for me to be more experimental with the perceived features and potential look of the device. Towards the end, the client chose a fliptop design which I had to modify based on a 3D model of internal components that the client provided later on. I was also instructed to built a 3D model of the final housing design for the given components, with the aim of producing printable 3D parts for building and testing a prototype.

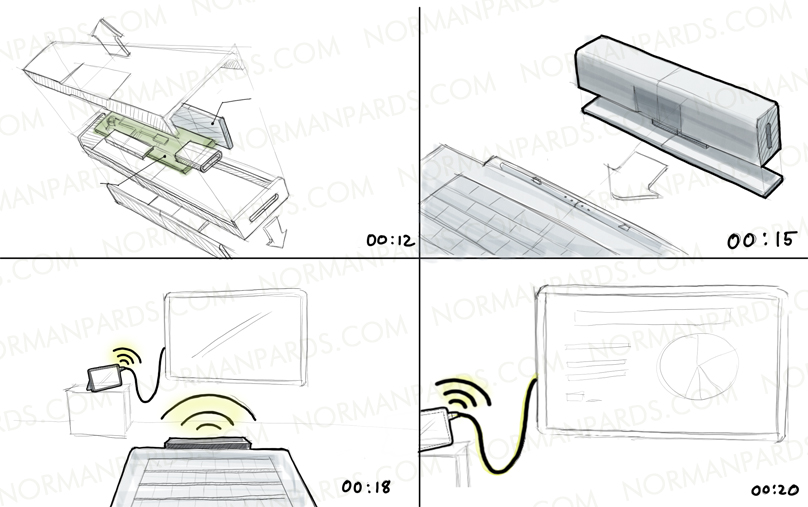

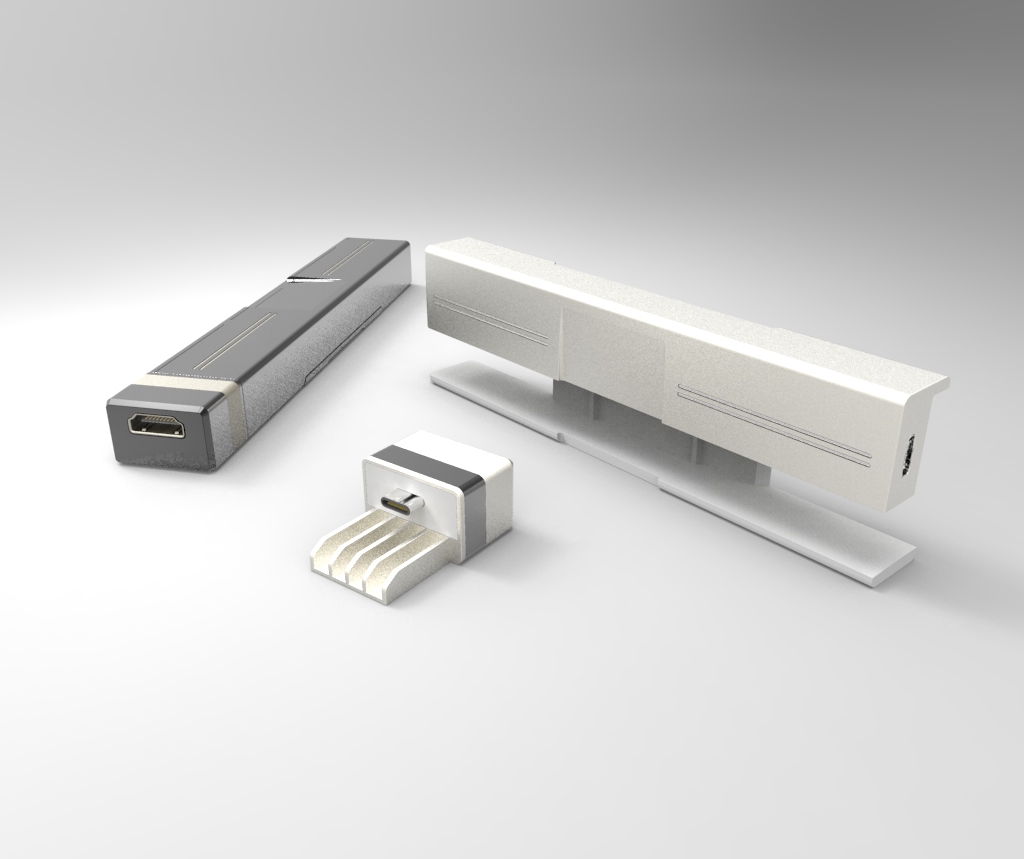

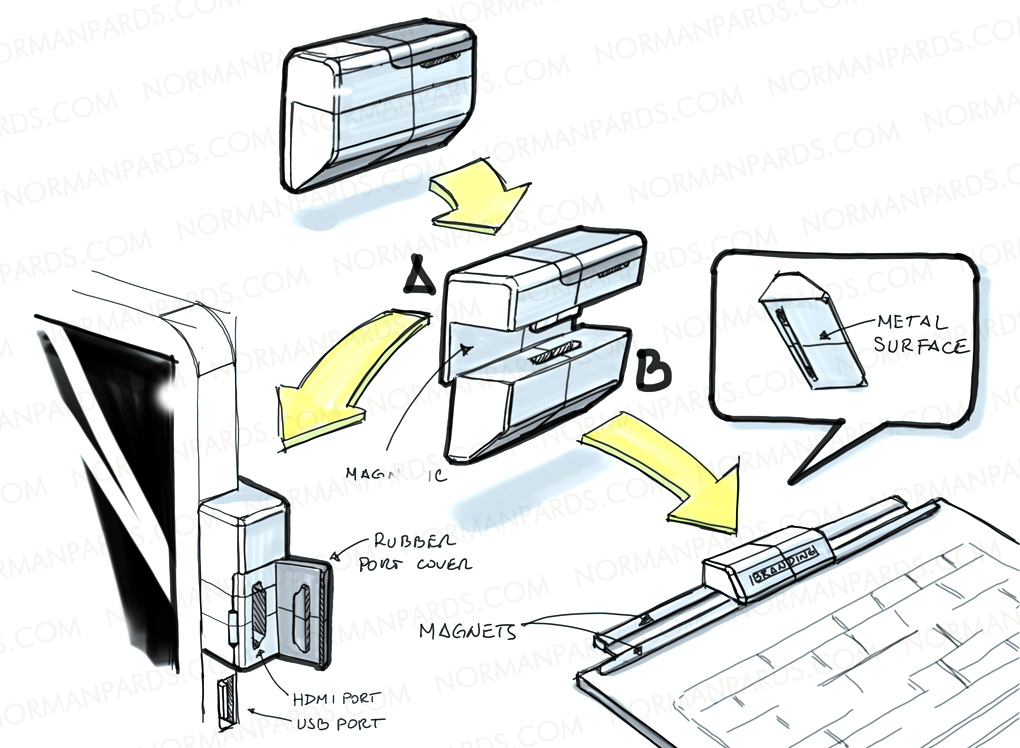

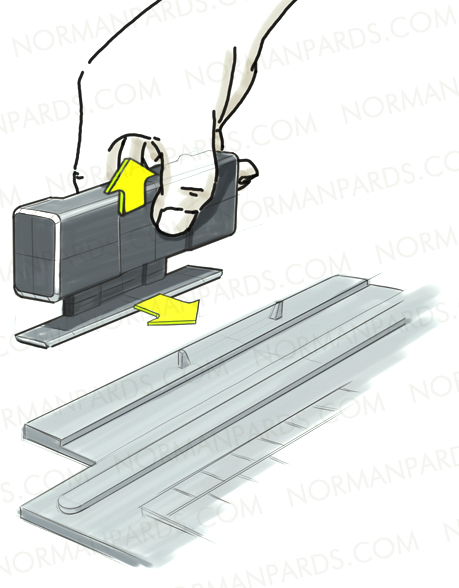

One of the projects I like the most are those that are simple, but very clear with their function and purpose — what the device needs to do, how it’s supposed to work and who are meant to use them. 2020 was the year when I was lucky enough to be awarded with such a project. The goal was to design a simple, sleek and handy device enclosure for a tech product that enables a specific type of wireless connection between a specific gadget and a television — quite different from bluetooth or wifi connections. The client provided 3D models of the internal component, from which I based my concept designs.

Figuring out how the technology attaches physically to another very specific type of device had been the challenge, and thankfully the client loved one of my ideas. Aside from asking me to build a 3D model of the enclosure for prototyping, the client also had me make storyboards and also a video showing the steps and benefits of using the device. Unfortunately, I have to defer showcasing those particular outputs in full for confidentiality.