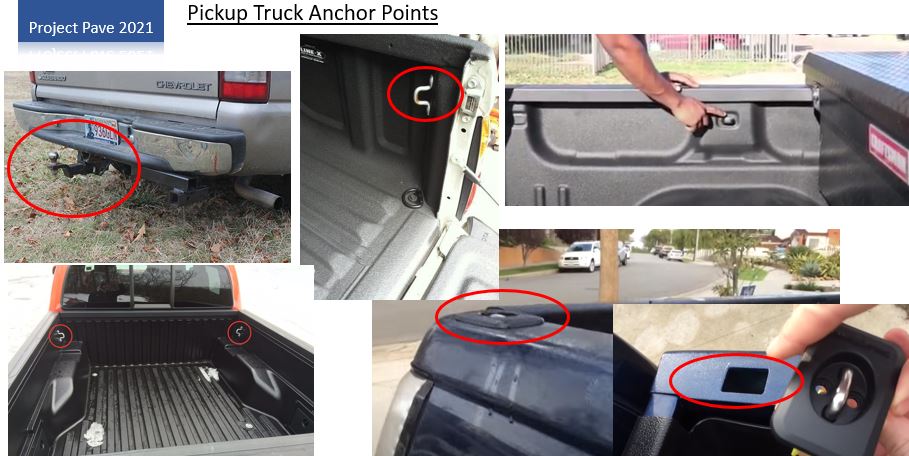

The project started off with a student thesis in 2021 aiming to develop a technology that would allow scanning and detection of road surface defects. One of the challenges is to design the equipment to rest securely on top of the pickup bed of any brand and model of pickup truck. This requirement was based on the need of the Department of Public Works and Highways, a government agency responsible for the upkeeping of national roads in the Philippines. So after the design briefing, I began the design process by looking into the variations of both old and current pickup trucks, including truck bed surface design, anchor points and accessories that attach to them.

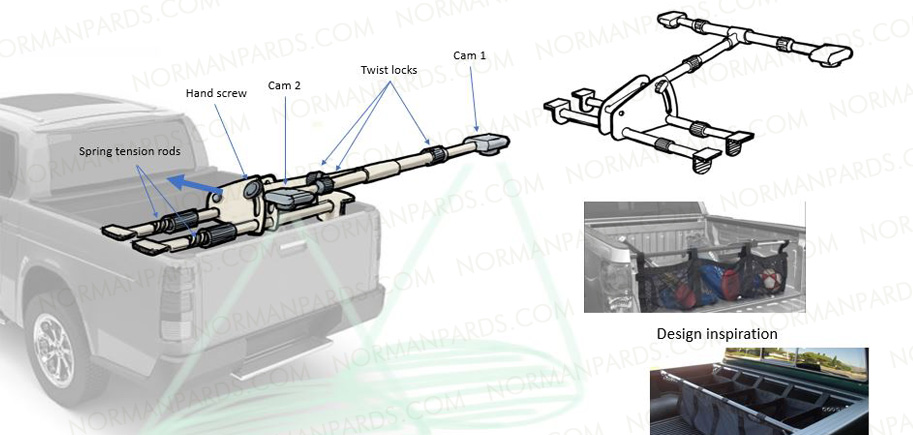

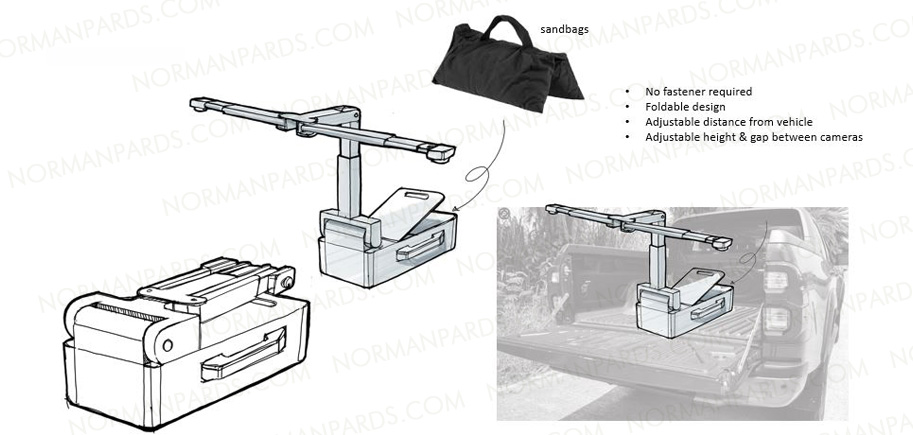

Another challenge to the design process was the project was at its early stages and the funding was quite limited. Therefore, I had to limit the equipment design to materials that are readily available in the local market, and affordable in terms of purchase and fabrication. There were still uncertainties with the tech setup during the start of the project, so we decided to focus the initial designs on the anchoring and positioning of the cameras.

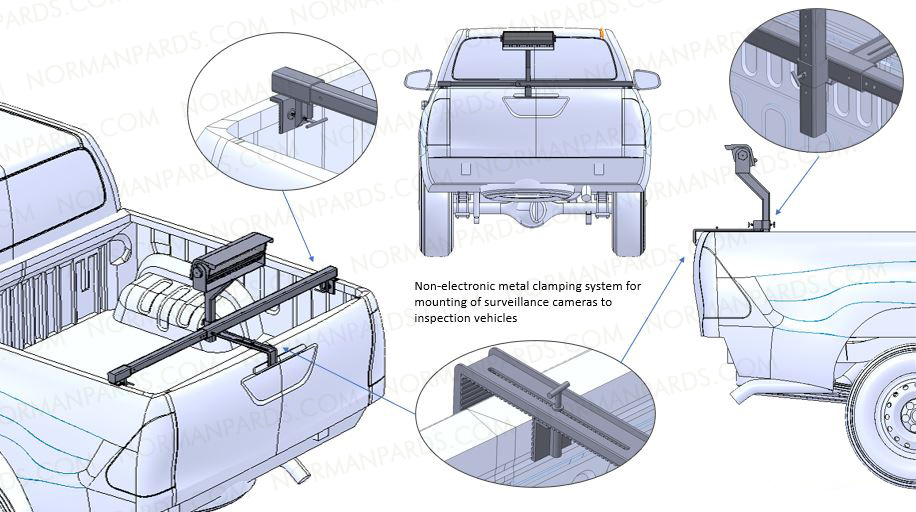

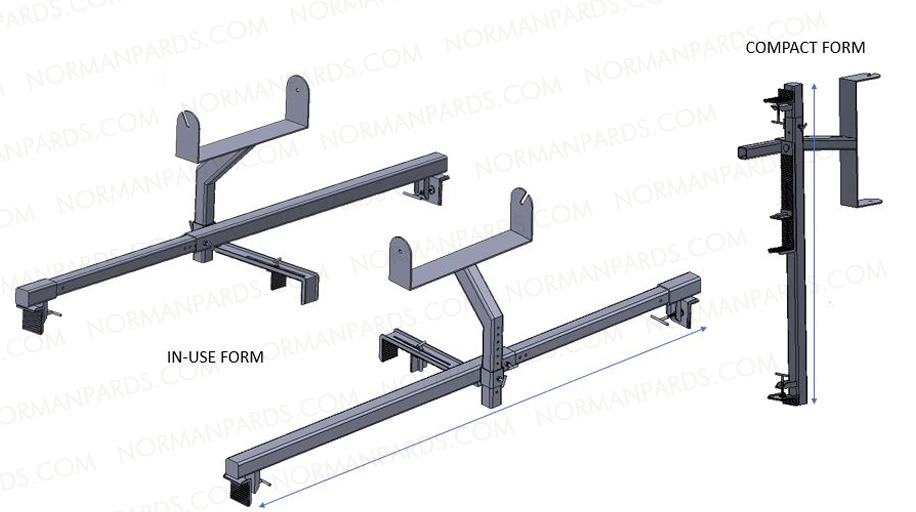

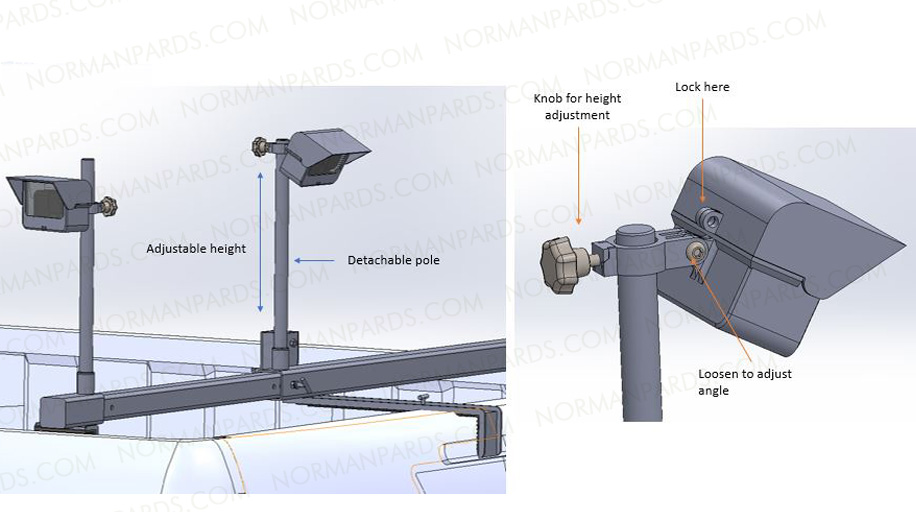

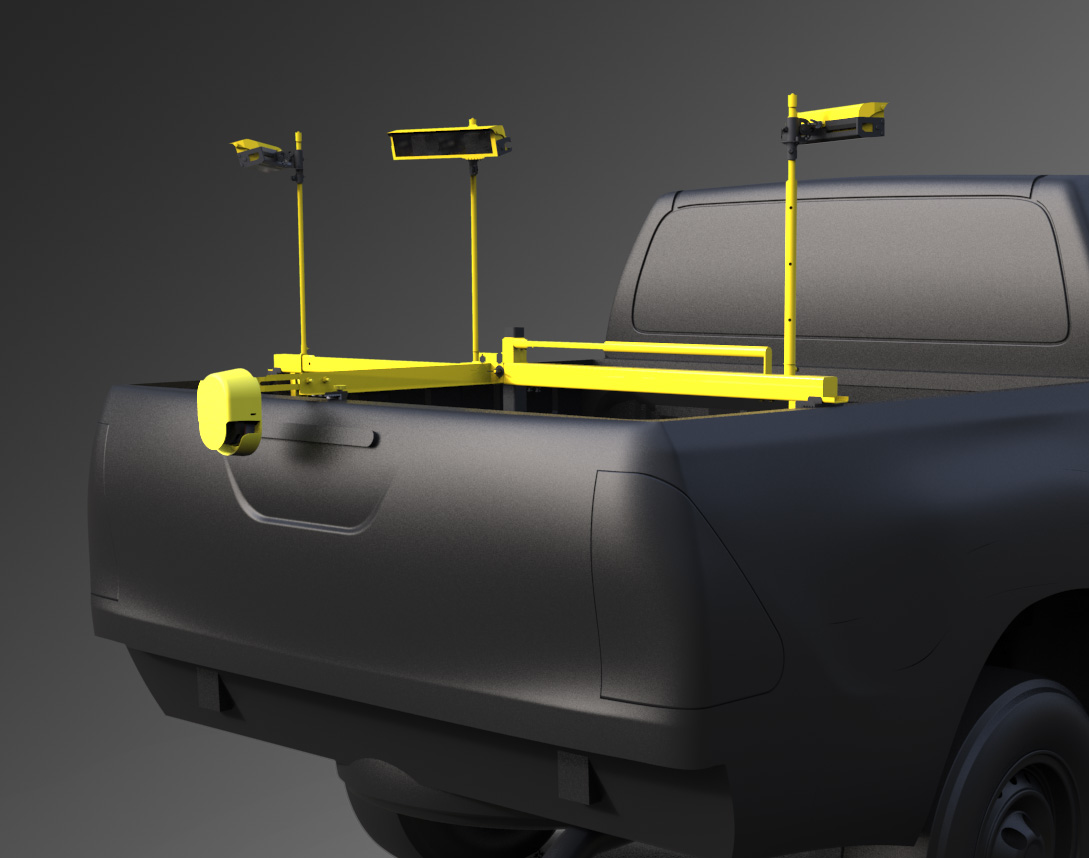

Overtime, the design evolved to accommodate the scanning technology and the first 3D model was created. Another challenge that was realized was the need for the equipment to become compact during vehicle transfer or for transport to different locations when necessary. I developed the design and we had the first prototype fabricated and tested on national roads.

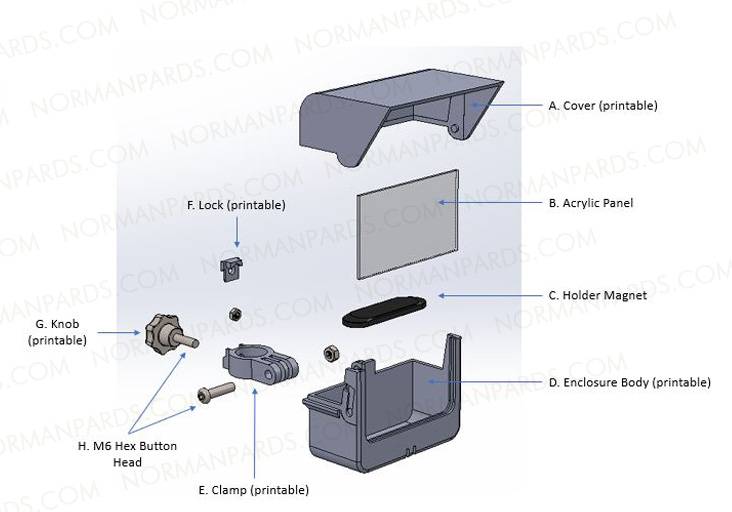

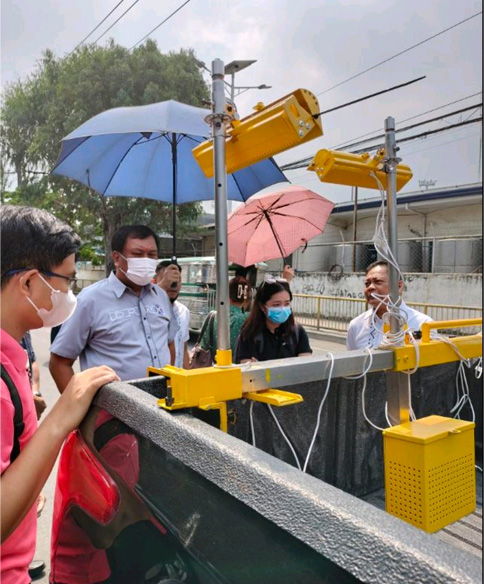

Feedback from the initial tests proved viability of the design, although there was much to improve on, including security of the clamping, heat management on the camera chamber and the need for additional cameras and sensors. I addressed the issues by making modifications to the clamping structure, and adding more slots for the camera assemblies. We also had variations of the camera chamber 3D printed for evaluation and testing, to explore the viability of using plastic instead of stainless steel.

Further developments were done with both the technology and the equipment design. In 2023, we had finalized the equipment which gained popularity and interest in government sectors and private companies directly involved in road structure development and maintenance. Today, the technology continues its development and the project is in talks with interested parties for further tests and implementation on national roads.

Special thanks to the P.A.V.E. project team for the opportunity, the experience and the collaborative efforts in making the project a success.

Leave a Reply